SiC Wafer Solutions 2025 SiC Substrate Application

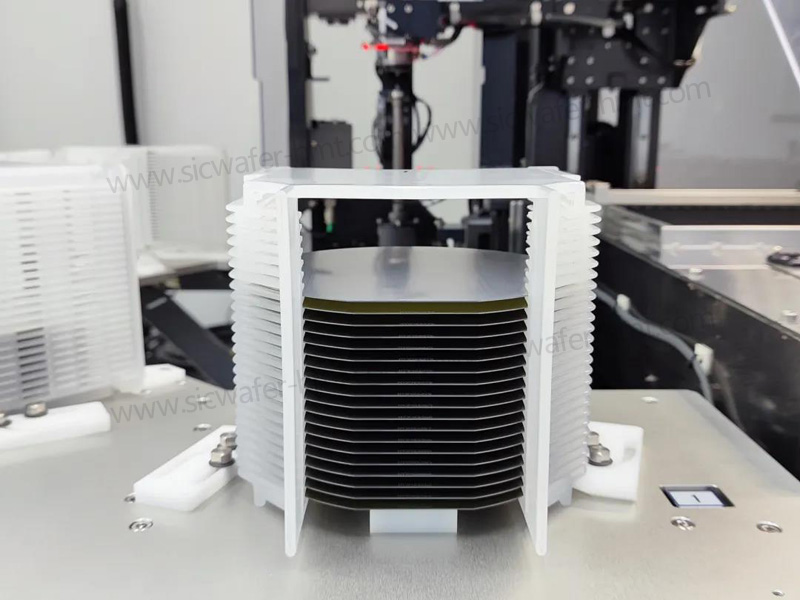

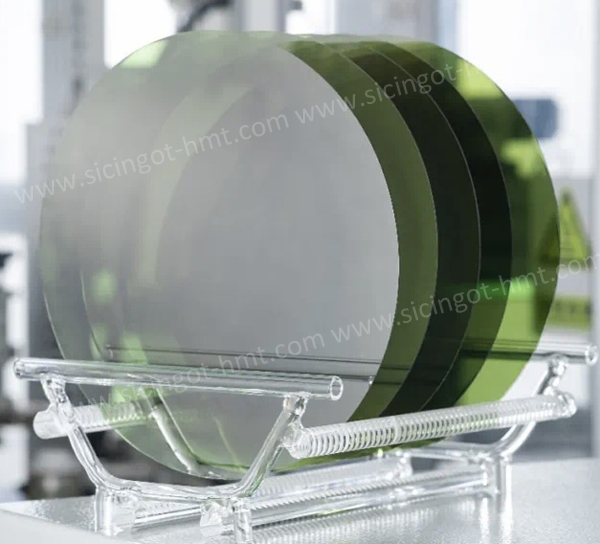

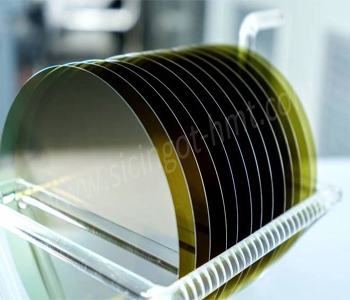

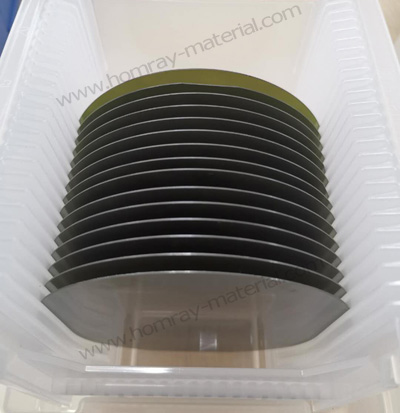

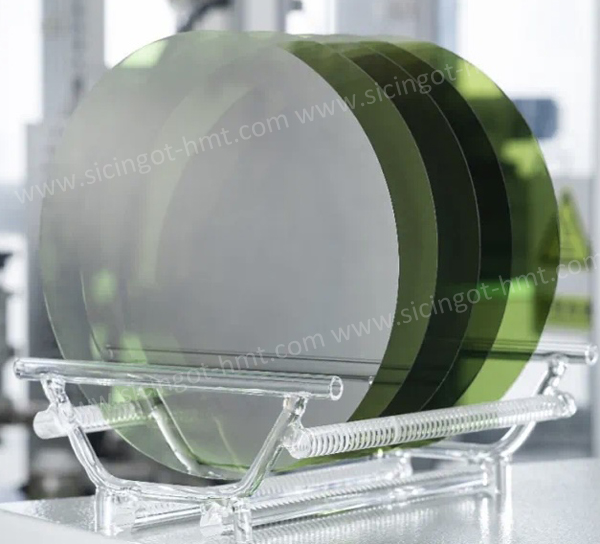

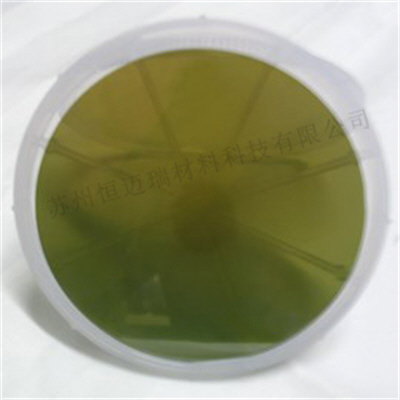

Grade: D/R/P Grade

Type: 4H-HPSI/4H-N

Dimension:2inch 4inch 6inch 8inch

Thickness:350±25um/500±25um

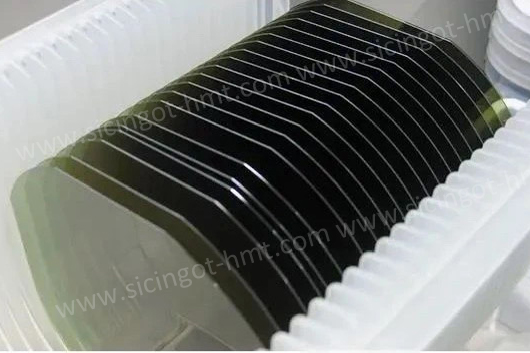

Product Description

The outstanding performance of DeepSeek has sparked a wave of artificial intelligence (AI) applications, driving rapid growth in the demand for AI data centers. HMT company foucs on manufacturing third-generation semiconductor wafers,like SiC Substrate, SiC Epitaxy Wafers and GaN on SiC Epi Wafers. We support SiC parameters customization and provide preferential price.

As the computational core of data centers, the power consumption of GPUs has increased from 700W to 2700W, or even higher. Consequently, the power supply requirements have also risen significantly, from the current 30 kW to an anticipated 300 kW in the future.

The high power consumption demands have led data centers to impose stricter requirements on the efficiency, power density, and thermal performance of power devices. SiC power conversion circuits can achieve higher conversion efficiency and power density, effectively reducing power losses and cooling needs. By 2025, it is expected that more data centers will adopt third-generation semiconductor devices to optimize server power systems, thereby driving their large-scale application in this field.

Other SiC Applications:

1. RF Devices: RF devices are components responsible for signal conversion in wireless communication, such as power amplifiers, RF switches, filters, and low-noise amplifiers. GaN on SiC RF devices combine the high thermal conductivity of SiC with the high-frequency, high-power RF output capabilities of GaN, meeting the requirements of 5G communication for high-frequency performance and high-power handling. They are gradually becoming the mainstream technology for 5G power amplifiers, especially in macro base stations.

2. New Energy Vehicles: Electric vehicle systems involve power semiconductor applications in components such as motor drive systems, onboard chargers (OBC), onboard DC/DC converters, and offboard charging stations. Among these, SiC power devices are most widely used in electric vehicle inverters. The use of SiC modules results in lower energy consumption, smaller size, faster charging, and longer driving range for the vehicles.

3. Photovoltaic Power Generation: Leading photovoltaic inverter manufacturers have adopted SiC MOSFET power devices to replace silicon-based devices. This improves conversion efficiency, significantly reduces energy losses, and greatly extends the equipment's lifecycle, offering cost-effective and high-performance advantages.

4. Smart Grids: With the national push for new infrastructure, ultra-high voltage (UHV) transmission projects have a significant demand for SiC power devices. Key applications in smart grids include high-voltage direct current (HVDC) transmission converter valves, flexible DC transmission converter valves, flexible AC transmission devices, HVDC circuit breakers, and power electronic transformers. SiC devices overcome the limitations of silicon-based power semiconductors in terms of voltage, power, and temperature, offering high frequency, high reliability, high efficiency, and low losses. They are driving innovation and development in smart grids through applications in solid-state transformers, flexible AC transmission, flexible DC transmission, HVDC transmission, and distribution systems.

5. Rail Transportation: Rail transportation demands better performance from its traction converters, auxiliary converters, integrated main and auxiliary converters, power electronic transformers, and power supply chargers. The adoption of SiC power devices can help achieve these improvements. SiC power devices significantly enhance the power density and efficiency of these power electronic systems, contributing to the reduction of the overall weight of rail transportation systems.

Related Products