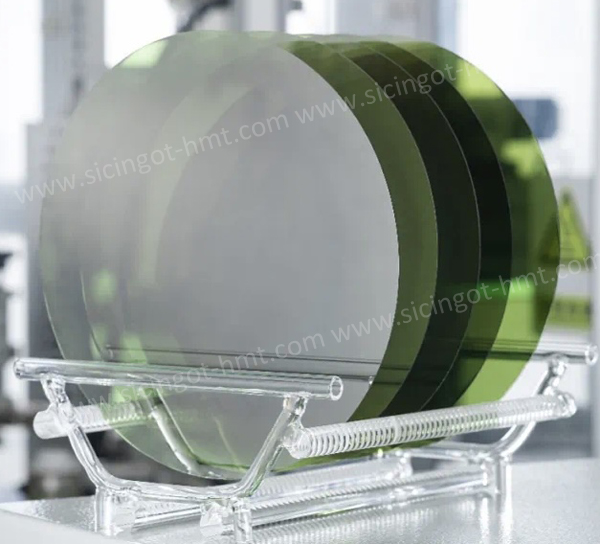

P Grade 8 inch SiC Wafer Manufacturer

Type: 4H-N

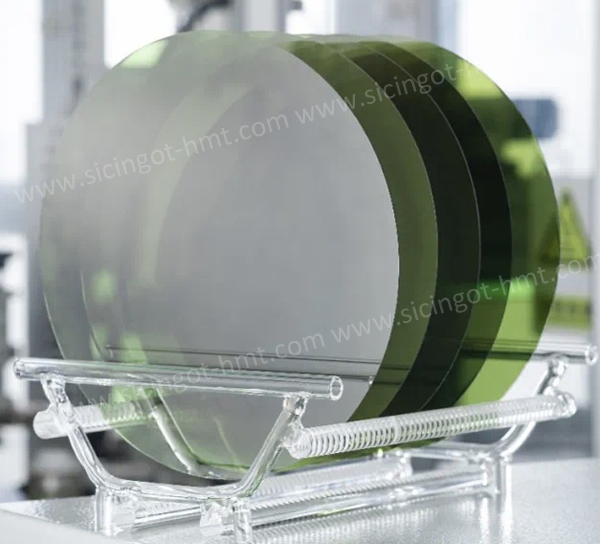

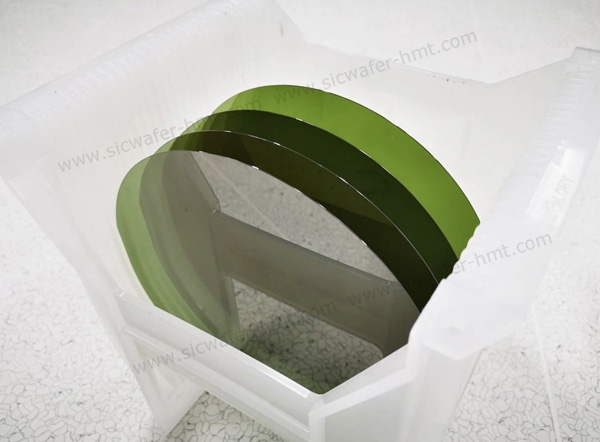

Diameter:200mm

Grade: Production

Product Name: SiC Wafer

Product Description

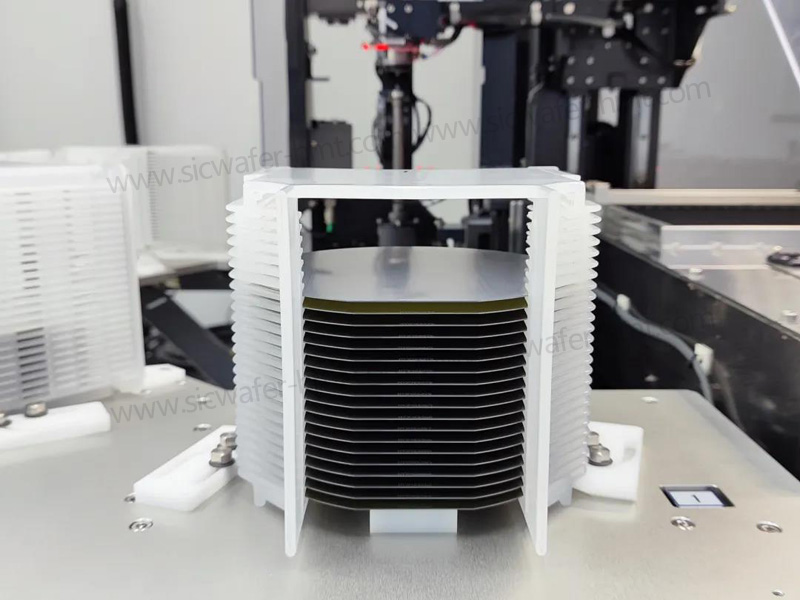

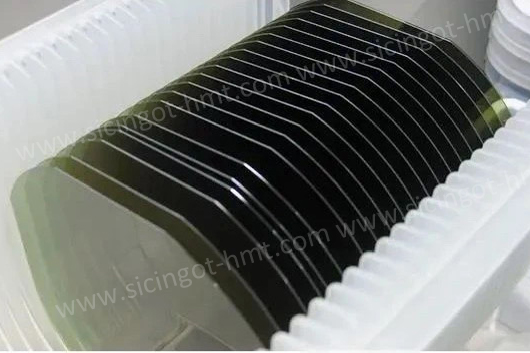

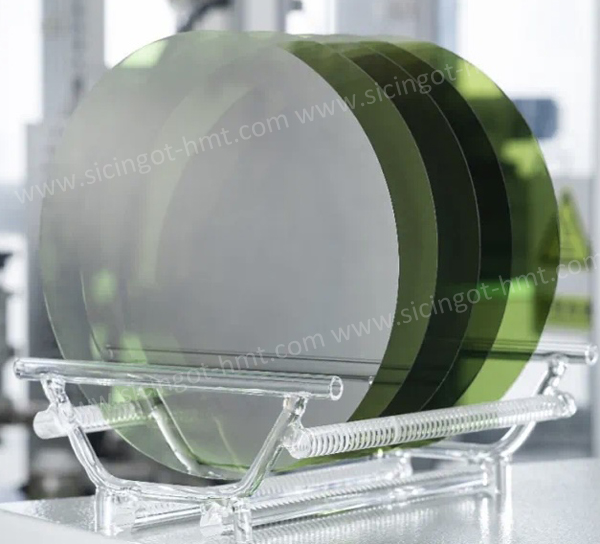

While 8-inch SiC Wafers dominate as the industry's premium standard with significant cost premiums, HMT can provide both conductive and semi-insulating 8 inch SiC Substrate. HMT has many years experience of SiC wafer from SiC Boule manufacture to SiC wafer slicing,lapping, polishing process etc...You can trust HMT as your SiC Wafer supplier always.

Core Technical Advantages

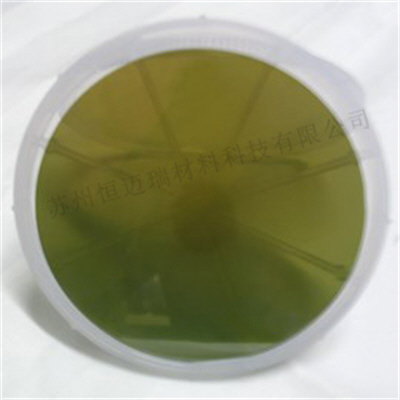

◆ Precision Geometry: 500μm±25μm thickness tolerance for enhanced process stability

◆ Optimized Conductivity: 0.01-0.03Ω·cm resistivity range for power device efficiency

◆ Full-Process Mastery: Vertical integration from boule growth to final polishing (CMP/etching)

Volume production discounts available with guaranteed <72-hour quote turnaround and flexible MOQ terms.

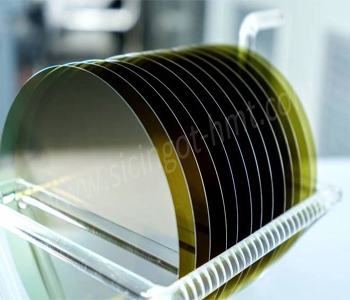

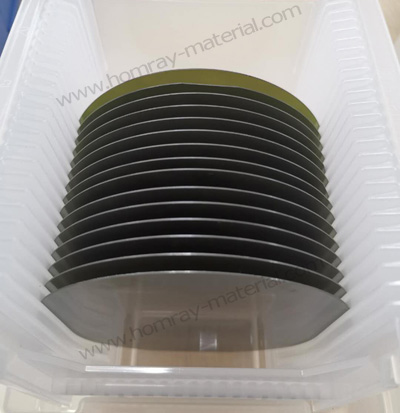

8 inch SiC Wafer

SiC is a wide band gap semiconductor material, also known as the third generation of semiconductor materials, compared with the first and second generation of semiconductor materials, SiC has a large band gap width, high breakdown field strength, high thermal conductivity, electronic saturation drift rate and other performance advantages.

Higher thermal conductivity, better heat dissipation. Temperature is one of the main reasons affecting device life, thermal conductivity represents the thermal conductivity of materials, SiC high thermal conductivity can effectively conduct heat, reduce the temperature of the device, maintain its normal operation, which makes the cooling system can be better optimized.

Related Products