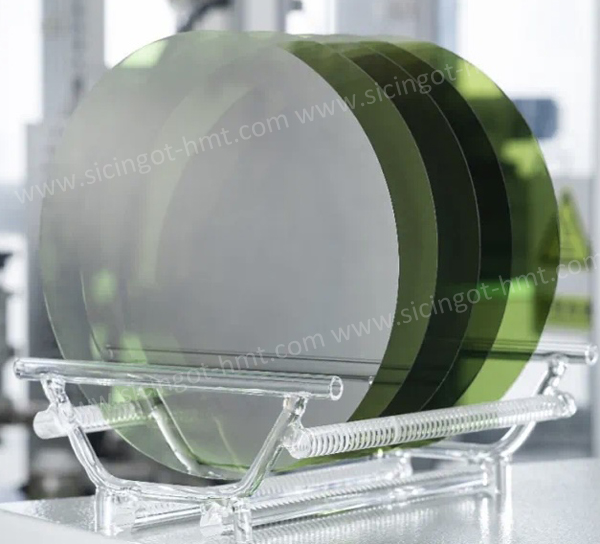

4H-N 8 inch SiC Substrate Manufacturer

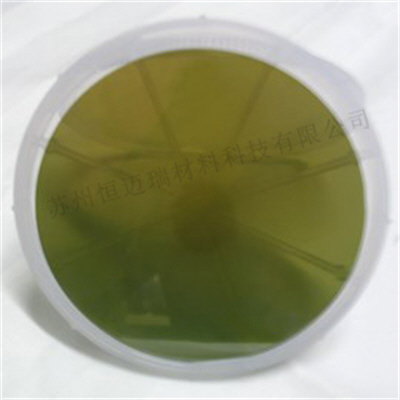

Type: 4H-N

Diameter:200mm

Grade: Mechanical

Product Name: SiC Substrate

Product Description

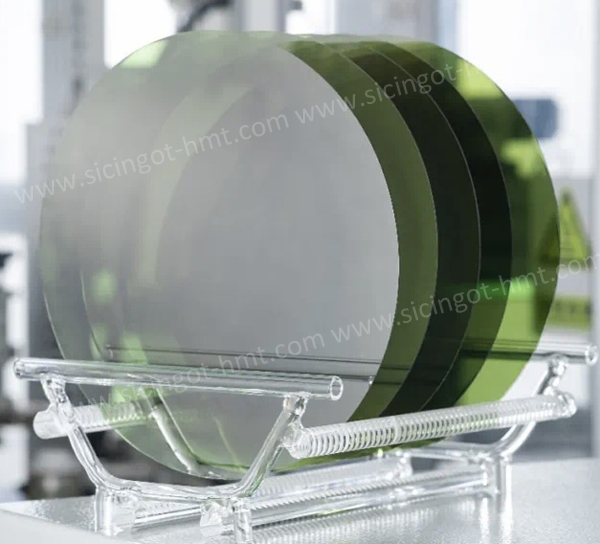

As the leading SiC ingots manufacturer, HMT can supply 8 inch 4H-N type SiC Substrate Wafer now,but only for small batch. Currently, most of SiC is manufactured on 4-inch and 6-inch wafers. The usable area difference between 6-inch and 8-inch wafers is approximately 1.78 times, which means that 8-inch fabrication will significantly reduce the cost of SiC applications. But why is the current market mainstream still 6 inch SiC substrate?

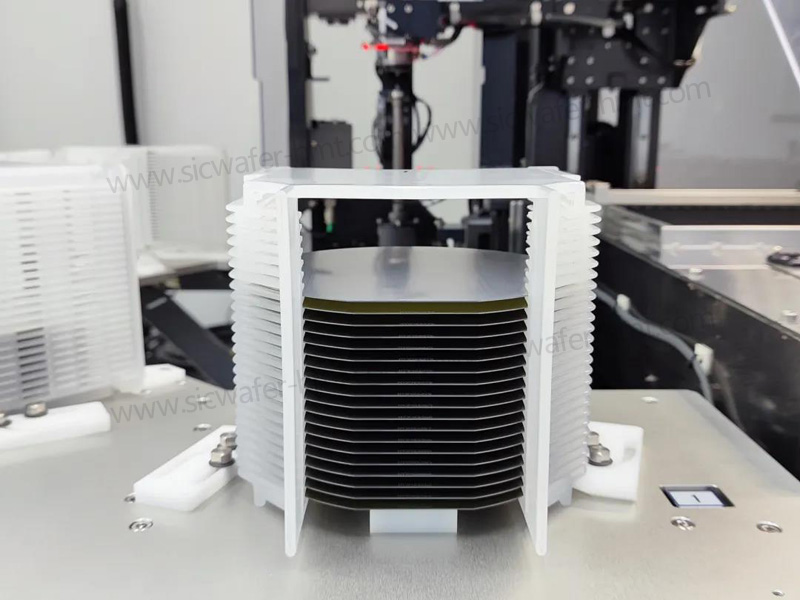

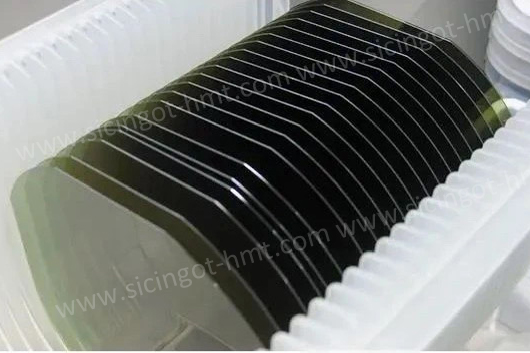

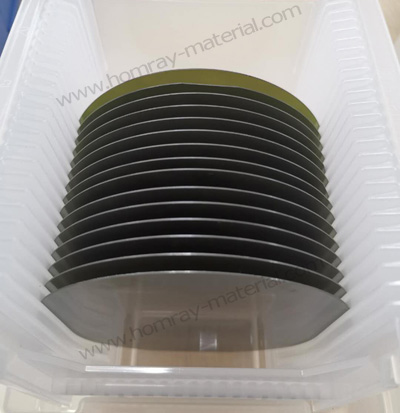

8 inch SiC Substrate Wafer 6 inch SiC Wafer

As we know, silicon wafers have started to move from 8 inches to 12 inches. Can silicon wafer production experience help SiC wafers develop to a larger area? Compared with silicon wafers, what are the difficulties in SiC wafer production?

Compared with silicon chips, the main differences between 8 inch and 6 inch SiC production are in high temperature processes such as high temperature ion implantation, high temperature oxidation, high temperature activation, and the hard mask processes required by these high temperature processes.

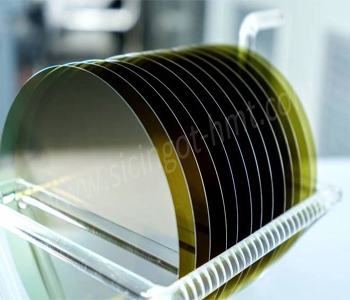

The manufacturing difficulties of 8 inch SiC substrate mainly focus on substrate growth, substrate cutting and oxidation process. In terms of substrate growth, the difficulty of substrate growth increases exponentially when the diameter is expanded to 8 inches. In the aspect of substrate cutting, the larger the size of substrate, the more significant the cutting stress and warping; Oxidation process has always been the core difficulty in silicon carbide process, 8 inches and 6 inches have different requirements for the control of air flow and temperature field, and the process needs to be independently developed.

Related Products