In recent years, SiC substrate manufacturers have accelerated the mass production progress of 8 inch SiC substrate, and at last year, the industry leader Wolfspeed has launched the world's first 8-inch SiC wafer fab, which also means that 8 inch substrates officially opened the mass production curtain.

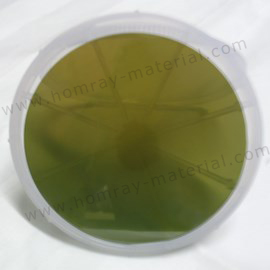

HMT produce high quality of 4H-N SiC Substrate both dummy grade and production grade. Meanwhile, we still supply 4 inch D grade SiC substrate wafer and 4 inch SiC ingot with reasonable price. Our 4 inch SiC wafer supply capacity is stable for the moment at least.

The effective utilization rate of 8 inch SiC substrate is high, and the effect of promoting the cost reduction and efficiency of the industry chain is obvious, especially when the value of the substrate in the SiC industry chain can be as high as 50%. The larger the SiC substrate size, the more chips can be manufactured per unit substrate, and the lower the unit chip cost.

For example, from 4 inch to 6 inch, the unit cost of SiC devices is expected to be reduced by 50%; From 6 inches to 8 inches, the cost of SiC devices is expected to be reduced by 20% to 35%.At the same time, while the SiC substrate size is expanded, the investment in the production line does not need to be too large, and the existing 8 inch silicon-based production line can be modified to produce 8 inch SiC devices.Therefor, the higher chip utilization area and lower cost of the 8 inch SiC substrate will change the market pattern.